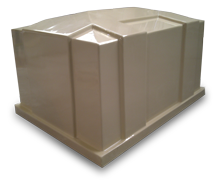

General Design

Fiberglass reinforced plastic (FRP) pump covers are designed for easy and rapid installation in areas of corrosive chemicals and high humidity. The exterior surface is Tan gel coated (other colors available) for attractiveness, excellent weatherability, and low maintenance.

Construction

FRP pump covers are constructed of fiberglass reinforced polyester resin, molded by hand lamination process. The exterior is gel coated with a FRP back up. The panel is then covered with 1" of rigid polyisocyanurate insulation: over which FRP is laminated, creating a rigid sandwich laminate. The pump cover is attached to a concrete base with a hinge.

Gel-Coat and Surface Coat

All gel coats and surface coating are a chemical resistant neopentyl glycol based polyester resin. Pigments are selected for their long term weatherability in corrosive applications.

Lamination Resin:

The laminating resin is a rigid orthophthalic polyester, suitable for use in corrosive conditions.

Insulation

Modified polyisocyanurate rigid foam one inch thick shall be used through out as insulation. Insulation has a K-factor of .14 BTU in/hr/ft/F degree, R-6.06 per inch. Insulation shall be completely encapsulated with FRP.

Maintenance

The Pump Cover is designed for low maintenance. It is recommended that the Pump cover be washed occasionally using water and a mild soap solution inside and out to prolong the luster of the finish.

Condition of Liability

The manufacturer reserves the right to alter details of construction, without prior notice; to the extent that the use of the building is not materially affected.

Specifications are unavailable